Even if Trump had lost, one fact remains: tens of millions of Americans voted for this guy three times in a row.

The first time, it's conceivable that Americans made a mistake.

The second time, they knew Trump as actual President.

The third time, they knew Trump as a convicted felon, insurrectionist and overtly wannabe dictator, and they voted for him even harder.

At this point, MAGA isn't a freak event, it's the norm. Even if the dems had won, they'd have won the presidency of a MAGA country, and quite frankly, what's the point... You can't cure someone who wants to be sick.

If you're bothered by social media votes, you need to go outside more.

Social media isn't real. It's a poor simulacrum of human interaction. Find real human beings to interact with and whatever they think of you, tell you, or how they treat you in your face matters.

But whatever people become and how they behave once they hide behind a screen and cast simplistic one-bit click-clicks to express complex human feelings and opinions doesn't.

What did George Washington ever do to deserve the insult?

It will be when the Trump voters discover that they will pay for the tariffs and not China.

I hate Elon Musk as much as the next guy - and all the more now that he has this massive conflict of interest working in his favor and at the American public's expense.

But I will say this for the sake of exercizing critical thinking: everybody is happy to say AI hallucinates when what it says doesn't suit their narrative, and call AI intelligent when it does.

YouTube Video

Click to view this content.

Interesting account of what happens before amputation in the case of frostbite, why surgeons wait as long as possible to amputate and how they try to salvage as much limb as possible.

MAGA ≠ republicans

It has a long piece of 1mm piano wire running through that acts as a spindle. It's a standard hinge design called a continuous hinge. I suppose I could have 3D-printed the spindle but it would have made the hinge huge and not very nice-looking.

Finding a prosthetist is a lot like dating. This is an extremely important, even intimate relationship. Here's how I've learned to tell the princes from the frogs.

That's kind of my problem: my correction is not simple. I can get near or far lenses with my correction for relatively cheap - like $100 a pair. But progressives are eye-wateringly expensive.

As for my frames, they're both free and priceless to me because I make them myself. And just because they're not off the shelf, they're more rewarding to wear.

So having some understanding and control of that part of the process could have helped.

The only things you can rely on with regard to how the lenses are edged is:

-

The bevel will be "bevelly" - meaning it'll be a bevel of some kind, between 90 and 120 degrees, but no flatter than that. In other words, you can rely on having something to grip the lens with and that's enough.

-

The bevel follows the curvature of the frame. If you frame is flat, the bevel will be placed all around the edge of the lens flat too.

-

As much as your correction will allow, the bevel will be placed as far forward as possible so the lens looks like it's tangent with the front of the frame all around, and all the thickness will be hidden at the back of the frame. So if your frame is, say, 2mm in width, the root of the bevel will be placed 1mm from the front of the edge.

The other thing you can rely on is that the bevel will be slightly oversized so they can be snapped into the frame, and the amount of oversize will be a bit higher for plastic frames which are more flexible. And that's where the danger lies: if your frames are designed to hold the frame without pressure like mine, you have to tell the optician so they pass the information to the lens cutter. Otherwise you will received lenses that are slightly too big.

But don't sweat it too much: the great thing with 3D printing is, even if the lenses you received aren't the right size, you can always print another frame with slightly revised dimensions.

And if you really don't want to print another frame, don't forget that you pay beaucoup bucks for those damn bits of plastic, so you can always copiously warn the optician that your frames are not made of the kinds of plastics plastic frames are usually made of, and then the onus will be on the lens maker to make the lenses right for your frames (remember that they will be sent your frames, so they'll know rightaway if the lenses fit).

If the lenses aren't right, it's their problem and you can reject the lenses and tell them to try again. If you warn the optician in no uncertain terms that your frames are PLA, they or the lens maker can't claim they didn't know.

Just design the frames you want with the shape you want, with a 120-degree bevel, and ask your optician if it's workable for the lens maker. They might tell you they'll ask them - and you can leave them a test print too if they want to sent it to the lens maker too. There isn't much more to this really.

I’ll definitely add cable temples to the list of things to try and see what works well.

Be aware that cable temples are a lot more finicky to adjust than regular curved temples. If they're too short, even a little, they'll dig into the skin behind your ears and you'll hate them. Likewise, if the hook is too narrow, the tip will hurt you under your ear.

That's a big reason why cable temples went out of favor in the 1920's: they're great when they're well adjusted, but they quickly become nasty and uncomfortable when they aren't - unlike maladjusted curved temples which can simply ride up the ear a little without too much drama.

With regular metal wire, you can bend the temples this and that way to make them fit. Not so much with PLA. You can shape it with heat but if you do it more than once, it becomes rough and unpleasant to wear - if the PLA doesn't delaminate completely. So take the time to design the right length and shape directly in your model. It's a bit long and tedious but once you know the right dimensions, you'll love how natural they feel.

Also, don't make the wire too thin or it will dig into your skin as well. And too thick will make the wire inflexible and difficult to put on. The wire profile that works best for me is this (for PLA):

They're prescription glasses. They're my regular glasses I wear every day. I made the frames but I can't print optical lenses, sadly. I wish I could because they cost a fortune and they're a real rip-off...

Halting the print to insert the magnets would be problematic: I print on the company's printer and it's a 5-hour print, so I start it before going home in the evening to avoid annoying everybody during work hours.

We're allowed to use the printer for personal prints. But the rule is, if someone arrives at the office and needs to print something for work, whatever private stuff is in the printer is removed to make way for work things. And of course, if the printer is running - or paused waiting for someone to attend to it - the print is cancelled.

So I'd have to arrive really early in the morning to make sure I get there before the most early birds but there are no buses at the wee hours of the morning. Therefore realistically, my long prints need to complete unattended and be ready to be chucked out in the morning if I'm not first to arrive at the office.

But I'm not worried about the magnets coming out: the fit is tight and I use really strong epoxy. I've yet to see anything assembled with that stuff come undone.

Thanks!

I just made one initial print but I didn't leave enough free play in the frame holder at the bottom of that case, so while it worked, it was kind of a pain to insert the frames into it. I widened the play from 0.4 to 1.5 mm and now there's zero usablility issue.

Another unexpected problem I discovered with that first print is that I couldn't tell the top shell from the bottom shell when the case was closed. I completely overlooked this and it turned out to be a massive PITA: 50% of the time, I would open the case upside down. Silly eh 🙂 It seems obvious in hindsight.

But I like the symmetry of it. So I added "engraved" text at the front edge to tell if the box is the right way up before opening, and put my name and a description of the particular correction in that case as a bonus.

The rest - stiffness, hinge, lid fit. magnet fit - came out okay the first time out. I'm getting really good at knowing the printer's tolerances in advance and leaving enough play for things that shouldn't assemble with an interference fit.

This is a custom case I made for my 3D-printed eyeglasses. https://github.com/Giraut/3D-printed_eyeglasses

I made this custom case for my 3D printed spectacles:

It holds the glasses by the edge of the frames, so the lenses are suspended above the bottom of the case without touching anything and no padding material is necessary to prevent scratching.

And being specially sized for those glasses, the case is no larger than it needs to be.

Did I mention that I love 3D printing? 🙂

Sounds like OptiBoard

The name rings a bell. Admittedly, I started looking into that stuff well before social media was even a thing 🙂

I didn’t realize you worked with a lens maker directly and not through an optician

Sorry I thought you meant to choose frames and for fitting. For that, I do my own, obviously.

But yeah, to order the lenses, I do have to go through opticians. And yes, they did measure my pupillary distance (only once, I'm not a shape-shifter), they do issue the order for the lenses in the correct format and they double-check the lenses when they arrive. Some of them tried to make me pay an extortion fee of $50 or something for bringing my own frames, but considering they wouldn't be doing any added-value work beyond ordering the lenses for me, I thought that was a bit rich so I went elsewhere.

I did order lenses direct from Hoya once, because I had a friend who worked there. But apparently they found out and my friend told me never again, or he'd be in trouble. So now I go through my local optician when my prescription changes - which isn't that often: the lady who owns the store knows me well, she's kind of amused to see my various eyewear contraptions and she knows she's never going to extract a fortune out of me, but also she doesn't have to spend any time on me either. So she passes her supplier's costs onto me almost without any surcharge.

I’m surprised to read that superglue is sometimes used

It's only for round lenses, either in light-fitting frames, for safety in case the screw backs out in metal frames, or in plastic frames because plastic is a bit more slippery. Round lenses typically shift when you clean them with a little too much gusto and it can happen surprisingly easily even in well-fitting frames.

Glue is not ideal but sometimes it's needed. And obviously it's never used with non-round lenses that are always naturally oriented properly.

Without the simulated weight, they’re fine. But with weight, they slip off if I look down.

Firstly, are you sure those test lenses you're using are polycarbonate? If they're glass, they're a lot heavier. And of course they might be thicker than necessary for your prescription because they're cheap: thin lenses are lighter but more spendy.

But essentially you've discovered why I always wear glasses with cable temples 🙂 Yes, they're a bit more annoying to fit in a case, but they hold your frames put on your nose and you never have to worry about your glasses slipping ever again.

Although the 3D-printed glasses I designed fold the temples at an angle to position the wires more smartly, so they fit in regular cases. And I've just finished designing a very nice 3D-printed custom case for them too, which I will publish on my Github soon. But here's a sneak preview:

Also, I've been wearing cable temples for so long that the nose bridge of all my glasses, which all land more or less at the same place on my nose all the time, ended up leaving a permanent indent in my skin. So the nose bridge always fall in it now. I could almost do away with the temples and the frames wouldn't even move at this point.

I think there isn’t an inexpensive way to do that.

If you don't intend to change the shape of your frames, the easiest is to design around old lenses you have lying around. If you screw them up, you weren't doing anything with them anyway so it doesn't matter. And presumably they used to be as nice lenses as you could afford when you wore them, so they should be close to the new ones you'll order after you've finished your design.

China did

Oh yeah, China... There's an economic and societal model I really dig right there.

it’s good and comparable to professional CAD software. But the learning curve is dumb

I have to agree on that. I feel I can only use FreeCAD because I've taught myself SolidWorks years ago and I know what to look for when I want to achieve something. Or said another way, when I want to do something in FreeCAD, my though process is always "In what roundabout, convoluted way can I do in FreeCAD what I used to do in 2 clicks in SolidWorks?". The only reason it works for me is because I know it can be done and I know the intuitive way it should be done.

I kind of have the same issue in Blender: I've been trying to teach myself Blender for years, but no matter how hard I try, it's just not letting me in. Unlike FreeCAD, I have never known any other software similar to Blender, so I don't know what I'm doing - or rather, what I should be doing - and it's excruciatingly frustrating.

That's the catch: you can't not use Google at all if you're online at all, because Google has managed to insert itself into every little corner of the internet.

And that's how the surveillance trap has quietly snapped shut on all of us without most of us noticing anything.

George Orwell had it wrong: the surveillance isn't conducted directly by a tyrannical dictatorship but subtly, indirectly by the private sector in cahoots with the government. And the date he predicted was 40 years off. Other than that, he was right: we live in a full-blown dystopia now.

Haha so many questions 🙂 Thank you for your interest in my little project.

To address you questions:

Is there some forum where people discuss this? For tips and common pitfalls.

There is not. Not to my knowledge anyway.

The few usetul forums I found are reserved for people who work in the eyewear trade and they don't want you to participate. I tried joining by pretending to be a professional, but they either found me out by asking where my store was, or because I asked questions that no true professional would ask.

What I know, I picked up over the years (decades really) making my own frames. But the opticians don't like it when you make your own frames, because selling you frames is their bread and butter. They make almost no money selling you lenses. So they won't help you undercut their business, that's for sure.

You talked about the registration tab at length. I’m making mine not entirely radially symmetric. Does this mean I don’t need them? Will the lens wabble inside because its PLA?

Your correction may or may not need orientation.

If you have a simple myopia or hyperopia correction, it doesn't matter how your lenses are oriented.

If you have astigmatism however, your correction has an axis and the lenses need to be oriented correctly to within a couple of degrees. You can see if your correction has an axis in your prescription: it looks like an arrow with an angle.

Progressive lenses are also oriented, because near is at the bottom and far at the top.

With non-round lenses, that's not a problem: the edging machine will measure your frames and cut the lenses so they're oriented correctly when mounted in the frames. You can't really mount them any other way.

With round lenses - or near-round - like mine, the lenses can turn in the frames and you need some way to prevent that. Round frames are really the worst possible choice if your correction is oriented. But hey, I like them 🙂

Traditionally, if the frames are made of metal, the hoops can be closed with screws, and tightening the screws clamp the lenses and prevent them from turning. With plastic frames, in which lenses are traditionally clipped - possibly after heating the frames a bit - the fit may be tight enough for the lenses to stay put on their own. If not, usually the optician will drop a drop of superglue at the edge.

Also, typically with round frames, the lens maker or the optician will make a very small, almost invisible mark on the lenses to find the correct orientation should the lenses move. If your glasses are round, look very carefully around the edge of the lenses and you should see the mark - usually next to something obvious like the hinges.

If your optician didn't make a mark, they probably figured they'd measure your correction again to find the optical axis on each lens (they'll draw 3 dots on each lens) and then they'll line up the 6 dots. But it's longer and more annoying than leaving a mark.

With my metal frames - which I made myself - the lenses are clamped hard in the hoops. No problem.

With my 3D-printed version, PLA is much too weak to take a thread to tighten the hoops around the lenses with screws (or take inserts) and printing hoops that lenses can clip into securely without opening them up is really fussy (I know, I did it for a friend's glasses I reproduced out of PLA). And I sure as hell didn't want to use superglue on my super-expensive lenses - not to mention, I want to be able mount them and remove them in minutes with no efforts.

That's why I designed split hinges that close around the lenses when mounting the temples, and this registration tabs system to lock the lenses in place without applying pressure on them.

If your correction doesn't need orientation or if you're designing non-round frames, you totally DO NOT need the registration tabs. It's only for round, oriented lenses.

Does the frame slip more than with other material? Or maybe with a riding bow make it not noticeable.

In my design, yes, because like I said, the lenses are held in the hoops with almost no pressure. without the tabs, they turn very easily.

If you design non-round lenses, they might "creak" a bit if you try to turn them forcibly and the frames don't fit very tight around the edges. But they won't slip.

If you're designing clip-in frames and the fit is correct, they won't move whatsoever. But you'll need to print several versions of the frames with a few dimensions adjusted ±0.05mm here and there to find the right size to clip in the lenses with no major drama, yet with enough pressure for a proper fit. It's really quite a lot of fuss.

Was the optician able to bend the temples with heat or was no frame adjustment needed at all?

I never go to the optician 🙂 I like being independent for things I need in my life (I'm also a partial foot amputee and I make a lot of my own shoewear for the same reason).

I used to adjust my 3D-printed frames a bit with a hot-air gun. It didn't take long but I didn't like the repeated trial and error process. So I took the time to work the adjustments in the FreeCAD models, as I explained on my Github, so the final frames fit my face perfectly without any adjustment, right out of the printer.

The only thing I do is polish the nose bridge with 600-grit sandpaper to smooth out the "staircase" a bit (layers of PLA deposited at a 45-degree angle) and then chemically-polish it even smoother with acetone. I also chemically-polish the inside of the ear hooks but only when I print them with certain PLA filaments I have that always end up a bit rough for some reason, if it's a pair of glasses I intend to be wearing for many hours continuously, so the hooks don't irritate my ears. But usually with most filaments, I don't have to: the wires are very smooth naturally out of the printer.

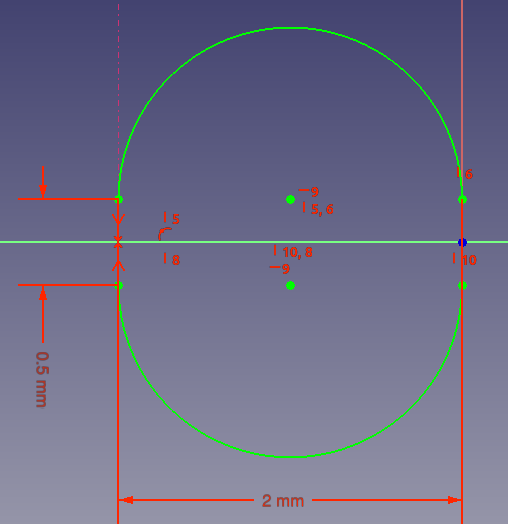

You’ve made the lens groove in this triangle shape. Is that the standard or will the tracer edger pick up any shape there? How’d you decide how deep to make that groove?

There are many types of bevels. But that type seems to be the most common for "regular" prescriptions on fairly flat or slightly curved frames. Depending on how thick your lenses are at the edges, the bevel is placed more or less forward by the edging machine to hide as much of the thickness as possible at the front when the lenses are mounted in your frame.

Usually grooves for that type of bevel are called "hide-a-bevel" grooves or V-grooves in the literature. They nominally have a 120-degree profile from what I could read. Although in fairness, I measured a few old lenses I had lying around with a profile projector and they measured between 90 and 120 degrees. So if it's a standard, it's not a very well respected one.

There are other types of grooves. The frames I made for my friend for example didn't have a groove at all: the groove was a 0.6mm square groove in the edge of the lenses themselves, and the bevel was inside the frame hoops. Very strange! I had never seen this kind before.

There are also chopped bevel profiles for ultra-thick lenses, and "shelf bevels" for wraparound lenses, etc... Look it up: there is an almost infinite number of bevel types. And that's just for solid frames: if you frames have a wire at the botton of the lenses, then the top half of the lenses have a bevel and the lower half have a groove. The variety is bewildering.

Lens makers usually look at your frames and mount the grinding wheel(s) with the correct profile(s) in the machine - or if the machine is fully automated, the tool changer loads the correct grinding wheel(s).

Often, they don't even need to look at the frames: if you chose a standard model at your local optician, more often than not, both the frames and the lenses are sold by the same supplier - and usually they're in Vietnam or somewhere all the way around the globe, which is why eyeglasses take so damn long to make, in case you wondered 🙂 But I digress...

Anyway, one thing you can count on with almost absolute certainty is that all edging machines are capable of cutting a "hide-a-bevel" 120-degree bevel. That's why I chose that "standard" for my frames.

As for the depth, you don't really choose it: it depends simply on the width of the hoop. My hoops are 2-mm in width, which results in a ~0.5mm depth because of the angle. I indicate it in the picture on my Github for redundancy, just in case, but it's not strictly needed: all the lens maker needs to know is that's it's a bog-standard 120-degree bevel, to load the correct grinding wheel into the machine, or something close enough to that profile.

How comfortable do you find wearing PLA so far?

The glasses are SUPER comfortable. It's not really because it's PLA or some other material: it's because the fit is perfect for me. It's like shoes or clothes: bespoke always feels better.

If you take the time to design your own frames to perfection - be it 3D-printed or made using traditional methods - when you hit the right dimensions, you'll know immediately: they'll be the most incredibly comfortable glasses you've ever worn. And when you do it yourself, you have all the time in the world to make the fit as perfect as you want it to be, something opticians don't have time to do because, well, they have to make their time worthwhile.

Finally, my glasses weigh 14 grams all told. That's VERY light and it goes a long way towards making them comfortable. That's definitely a plus and it's entirely due to the 3D-printing process.

I hope the above answers your question 🙂 I wish you good luck with your own design endeavor

People coming here to rant about Reddit isn't activity.

It's getting quite good, and considering what I paid for it, it's very very good indeed 🙂

It seems to be lagging behind by hours.

For instance, this thread on lemmy.world shows 5 comments and 56 upvotes, while the same thread on lemmy.sdf.org has 3 comments and 24 upvotes only. And the weird thing is, I posted this thread from lemmy.sdf.org, as well as one of the comments, and outgoing is instantaneous. It's just incoming comments and votes that don't seem to come through.

CAD files of my 3D-printed eyeglasses and instructions to order the lenses and mount them - Giraut/3D-printed_eyeglasses

You might recall last month that I posted about my 3D-printed spectacles.

Enough people asked me for the files and for details on how to order lenses and mount them into the frames that I figured I'd release everything with instructions - and also redesign the hinges a bit so the temples fold more compact, something I meant to do for some time.

You might find this little tool useful:

This is a block with a series of vertical and horizontal holes from ⌀1 mm to ⌀3.6 mm (nominal) in 0.1-mm increments. I print this block with any new printer / new material at the layer thickness and speed I use most often and keep the blocks as references.

Then, when I want to print a part with a hole in it that will end up printed at the final diameter without any rework (or very close, but usually it ends up exactly right) I use the gauge block I printed with the printer and the material I intend to print the part out of to find out which nominal diameter hole I need to use in the model for the hole.

For instance, the block in the photo was printed on a Prusa Mk4 with PLA at 0.2 mm layer thickness. If I want a ⌀0.8-mm vertical hole with no interference in my final part in PLA out of that printer, I'll need to model a ⌀1.2-mm hole. I know that because the shank of a 0.8-mm drillbit will slide freely in the vertical hole marked ⌀1.2 in the block.

Or if I want a hole that I can screw an M3 screw into without having to run a tap through it, the block tells me I would have to use a ⌀3.2-mm hole to fit a ⌀3-mm pin in freely, and I back off 0.4 mm to get a hole in which the screw thread will engage well but reasonably lightly, or 0.5 mm for a tighter engagement (but with a bit more risk with horizontal holes near an edge, because the layers might separate) so I know I'll have to model a ⌀2.8 or ⌀2.7 hole in the model.

I use those gauge blocks all the time. They save me a lot of time on parts that I print often because I never have to ream or thread the holes: they come out the printer just right and ready to use.

This is an example of a 3D printed living hinge that also doubles as a spring made with PLA. The material isn't usually the best choice for flexible applications - especially when the living hinge ...

This is the worst possible setup to print living hinges: PLA isn't terribly flexible, and here the flexible bits have to be printed vertically, which really isn't ideal to withstand cracking.

Yet when the application isn't heavy-duty like in this clamp-on connector, even PLA printed "against the grain" works well too: this connector can spread its hooks linearly 3 mm apart and the living hinges don't crack or weaken even after many cycles.

I'm generally left-learning and I enjoy the usual left-leaning comedians - you know, TDS, Colbert, Kimmel and the likes.

But I also pride myself on being open-minded and listening to all sides, and I don't know any good right-leaning comedians. And ya know, if it's funny, I'll laugh at anything said by anyone.

So please make suggestions! Whose jokes and commentaries are worth listening to?

And in case it wasn't clear, this is NOT flamebait: I'm genuinely looking for good comedy material from comedians on the side of the political spectrum I'm not on, for my own education.

Testimonies from therapists and users with Cerebral Palsy, Arthritis, AFOs, Braces, Strokes, Fine Motor skill issues, Autism, Parkinson's, Guillain Barre Syndrome, Paralysis, One Hand, Prosthetics, Developmental Delays, Special Needs, Braces, Handicaps

So I'm on the market for a 4G or 5G mobile hotspot with a build-in VPN client I can carry around in my backpack and connect my cellphone to. I've looked far and wide, and really the only manufacturer that seems to make what I want is GL.iNet.

The two battery-powered models they offer that interest me are the Mudi v2 and the Puli: they only do 4G and I wish they did 5G too, but I can live with that. Other than that, they really tick all the boxes for me.

From what I could read, the GL.iNet company also seems very open and very responsive. That's a plus too.

But I have one giant problem that prevents me from whipping out the credit card: GL.iNet is a Chinese company, and those products are sensitive applications. I know I can flash OpenWRT separately on those devices to ensure they're not doing stuff behind my back, but I don't really want to do that because I'd lose the GL.iNet plugins and custom UI. Not to mention, I have no free time for that. I'm looking for a ready-made solution if possible with this one.

Anybody knows if GL.iNet can be trusted?

Also, has anybody ordered from Europe using their EU store? They say they ship direct from Europe but they give no details.

And finally, what do you think of those two mobile VPN routers if you own one. Do they work well? I read somewhere that they can be buggy with certain VPN providers. Do they work in Europe? I assume they do since they sell EU plugs but maybe there are caveats.

I'm investigating getting off the cell network permanently to avoid at least the constant triangulation of my position. I figured I'd look into getting a VoIP number and getting calls and texts over WiFi. I don't mind being unreachable when I'm not connected to a hotspot, so it's not a problem for me.

But before looking for a good VoIP provider, I decided to check if WiFi still worked in airplane mode. And indeed it works. But to my surprise, when I connected the WiFi, my cellphone provider's name also came right back up at the top right of the screen. In airplane mode? What the hell?

Long story short, after investigating a bit, I realized I had WiFi calling enabled. So I can in fact already get calls and texts without being on the cell network.

And I'm thinking, maybe that's good enough for privacy?

I mean I know SIMs leak information like ICCID / IMSI / IMEI so obviously they have no reason not to do that over WiFi also and that's not so hot.

But on the plus side, none of that information is linked to cell towers and location anymore - at least not precise location if I'm not on a VPN - the baseband processor is off and can't do whatever shady chit-chat it does with the SIM and the cell towers, and I can still use my normal phone numbers without having to change and tell a million people that I have new numbers if I go with VoIP.

Also, I don't store my contacts on my SIMs and I use a deGoogled Android. So I figure that limits how much adversarial software can exploit the SIMs to leak data.

So it seems to me that WiFi calling may be a good solution for me for better privacy without too many compromises.

Can you think of something I missed that I should know before using this feature?

During Disability Employee Awareness month, we call out the medical tech industry for fighting disabled people's right to repair or modify the tech that they own.

I finally have an appointment to get my problematic residual phalanges taken care of. The hospital created an account for me into their fancy-shmancy "My Recovery Path" online system, in which they told me I'd find messages about my care, imaging results, appointments and the likes.

So I logged in to check it out, and I found my first automated message in the inbox - a 5-page PDF that went something like this:

> Welcome to your My Recovery Path account! > > You've been referred to the Foot & Ankle team for RESIDUAL TOES REVISION. Before your first appointment for RESIDUAL TOES REVISION, here are helpful documents to help you deal with common toe problems. > > - Best footwear for bunions > - Avoiding blisters on hammertoes > - How to care for diabetic toes > - Trimming ingrown toenails safely > - Reducing hallux rigidus pain > - ...

Like... Really?

Clearly the word "toe" in my referral triggered the sending of this boilerplate.

I realize whoever programmed this system means well, and the hospital means well too. And I can see this system is convenient as a one-stop shop to get information about my problem and communicate with the doctors. But the automatic "helpful" advice is a bit depressing...

YouTube Video

Click to view this content.

Exoneo makes 2 prosthetic feet: the Mahi for moderate to high activity levels and the Upya for low activity.

Both have a spring block under the heel and spring-loaded "metatarsals", which helps push-off when walking:

https://youtu.be/YeZNaM0NaNc

You can even assemble and size them yourself:

https://youtu.be/XjdDyo69JJU

More interestingly, it seems the company has a lot of customers in developing countries, meaning there's a very good chance those feet are affordable. Sadly, I couldn't find prices and I didn't want to request a quote for nothing.

I did find an independent review of the Upya foot (in French here, automagic translation here, accompanying video here), so at least it's not like all the information I could find comes solely from the manufacturer.

The reviewer confirms that the foot was competitively priced: although he doesn't disclose how much he paid for his foot, he does say it's "a prowess considering the price at which it's sold". That bodes well.

So I've been exploring the fabulous word of additive manufacturing for a few months now with my company's 3D printer - a Prusa Mk4 - that we employees are welcome to use for our own personal use when it's not busy printing tooling for work of course.

I've gotten really good at squeezing the most performance out of that thing: some of the functional parts I made with it at scales that are pushing the boundaries of what regular PLA out of a 0.4-mm nozzle can be coaxed into becoming, I'm properly proud of.

And I'm having a lot of fun finding ways to overcome the limitations of FDM. I don't really want a more precise printer: half the fun is witnessing a part that shouldn't exist come out of a printer that doesn't really have any right to be this good. Pushing the envelope... It's the spirit of hacking in the world of 3D printing and I love it!

But now I'm wanting a printer of my own. The company's printer is fine and all but when it's doing work-related things, I can't use it. And I have to wait to go back to work the next day to print something I modeled the evening before.

So I'm on the market for a good fast FDM printer that can print prints with different filaments at the same time, because I'd like to experiment with stretchy materials but keep using rigid and cheap materials for the supports, and also to play with colors. And I think I want a core XY printer because I've run into problems with big heavy prints with the company's bed slinger.

And finally, something that's really important for me: I want something as open source as possible that doesn't phone home, and ideally not made in China.

Money is not tight. The kids are out of the house and I have a well-paid job. I set my budget to 5k - dollars or euros.

So with those requirements in mind, from what I read, the best option for me is to stick with Prusa: it's more expensive for what it does but it's not sketchy Chinese spyware. Also, I know the brand already and I've been nothing but happy with it so far.

And in the Prusa line, I'm tempted by the XL with an the bells and whistles - namely 5 heads and an enclosure.

But here's the thing: I hear this machine has problems. Is it true? Would you have a better suggestion? Possibly another brand that I should consider?

Maybe there's something I don't understand here. I'd love it if someone told me how to do the following.

Let's say I have some really complex shape in a sketch left of the Y axis: it takes me forever to get it just right. Then I need to mirror it on the right side of the Y axis and connect the two halves.

In SolidWorks, it's trivial: mirror the stuff, done. If you change the master shape on the left, the change is reflected on the right.

In FreeCAD, the best you can do is make a mirror copy of the left-hand side elements - which also makes copies of the constraints which are completely independent from the original constraints on the left-hand side - delete the stupid new right-hand side constraints and slowly, painfully constrain the right-hand side copies to the original left-hand side elements, trying to dodge the dreaded orange over-constraints all the time. It's long, it's painful, and the end-result is usually so fragile that if you change anything significant on the left-hand side, the sketch turns orange and then it's back to hunting broken constraints again.

Surely it can't be that painful. Am I missing something obvious?

I had new progressive lenses made, but the old ones are still fine and don’t have a scratch. They’re just a bit weak at near distance, but otherwise perfectly serviceable.

So I made new frames for them because I don’t like to throw away things that work.

All assembled, the frames weigh 3.5 grams, and 14 grams with the lenses mounted.

This was printed with a Prusa Mk4 and regular PLA at 0.15 mm layer height. The hinges use simple 10x1 pins - and I worked my magic to print the holes horizontally to the final dimension with interference fit, so no reaming or drilling is necessary. These glasses are straight out of the printer with zero rework.

I think they look pretty good as they are. If anybody notices they’re 3D-printed, I’ll say I’m gunning for that particular style 🙂

The front of the frames prints in 11 minutes and both temples in 12 minutes. I could break and make a new pair every day for the rest of my life and it would still be faster and cheaper than going to Specsavers only once.

I had new progressive lenses made, but the old ones are still fine and don’t have a scratch. They’re just a bit weak at near distance, but otherwise perfectly serviceable.

So I made new frames for them because I don’t like to throw away things that work.

All assembled, the frames weigh 3.5 grams, and 14 grams with the lenses mounted.

This was printed with a Prusa Mk4 and regular PLA at 0.15 mm layer height. The hinges use simple 10x1 pins - and I worked my magic to print the holes horizontally to the final dimension with interference fit, so no reaming or drilling is necessary. These glasses are straight out of the printer with zero rework.

I think they look pretty good as they are. If anybody notices they’re 3D-printed, I’ll say I’m gunning for that particular style 🙂

The front of the frames prints in 11 minutes and both temples in 12 minutes. I could break and make a new pair every day for the rest of my life and it would still be faster and cheaper than going to Specsavers only once.

The HVAC service provider I contract with to do the yearly maintenance on my A/C is overcharging me because I "hacked" my A/C. I kid you not!

The service guy came today because the A/C blows cold on heat setting. He asked me to turn the A/C on to demonstrate the problem. I couldn't find the remote, so I pulled out my Flipper with the Mitsubishi A/C Remote app - which works fine and which I regularly do when I can't be bothered to go get the remote on the wall when I'm on the couch. The thing turned on, blew cold, so the man set to work.

2 hours later, he comes back with a circuit board telling me he had to change the control unit. Okay fine. And now I get a bill from his company showing a surcharge for extra service work due to unexpected "damage to the electronics caused by an unauthorized piece of equipment".

What the actual f...

Needless to say, I'll be contracting another company next year.

It's that time of the year again.

It happens to me once or twice a year: all ten toes itch like a mofo. It comes at random, but usually around fall and spring. It might have something to do with large temperature changes, but no matter what I wear, I still haven't found out how to prevent it happening.

I've tried a massage, hot mud pads, cold gel pads, icy-hot balm, going to the sauna, painkillers (the non-addictive kind), and I'm nearing the bottom of this small bottle of bourbon because it's driving me insane.

If anybody has any suggestion, I'm all ears.